Dynamic power output

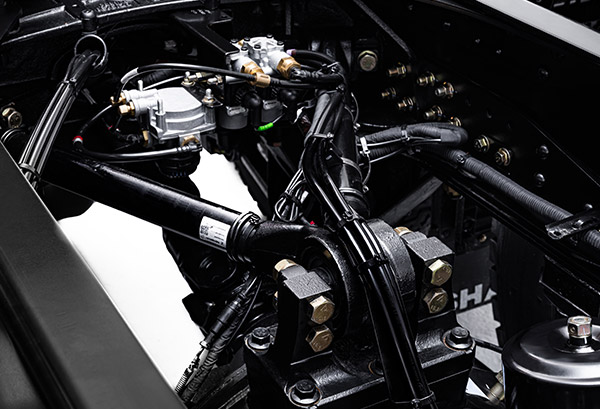

The engine of the X3000 is designed to dynamically adjust its power output in response to the vehicle’s load weight, thereby enhancing the vehicle’s fuel efficiency. This adaptive power management contributes to a more economical operation and reduced environmental impact.

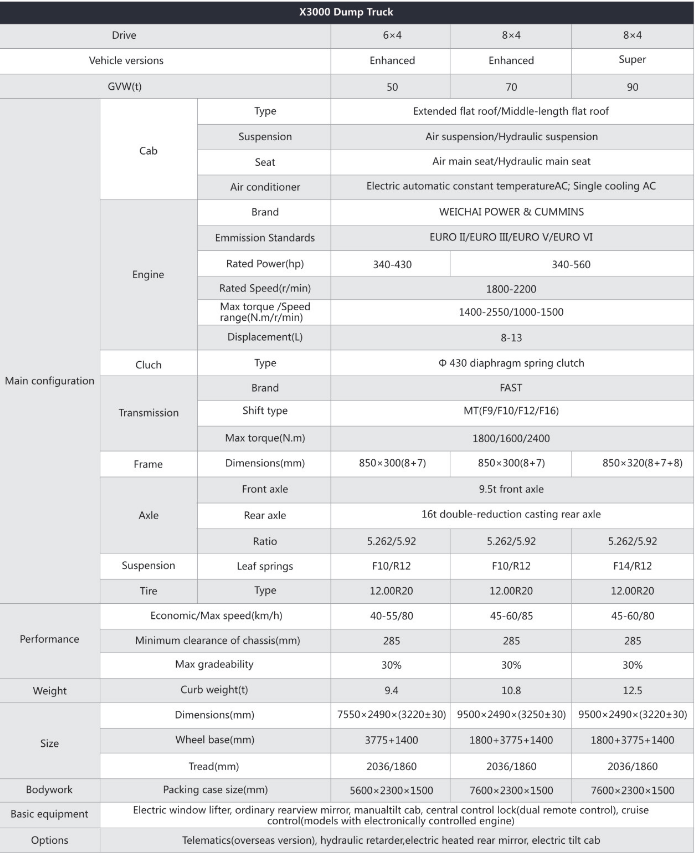

Twin-shaft gearbox

The twin-shaft gearbox features an innovative design that minimizes fuel consumption during long-haul transportation. Additionally, it delivers robust performance across a variety of challenging driving conditions, including hilly terrains, winding roads, and congested traffic scenarios.

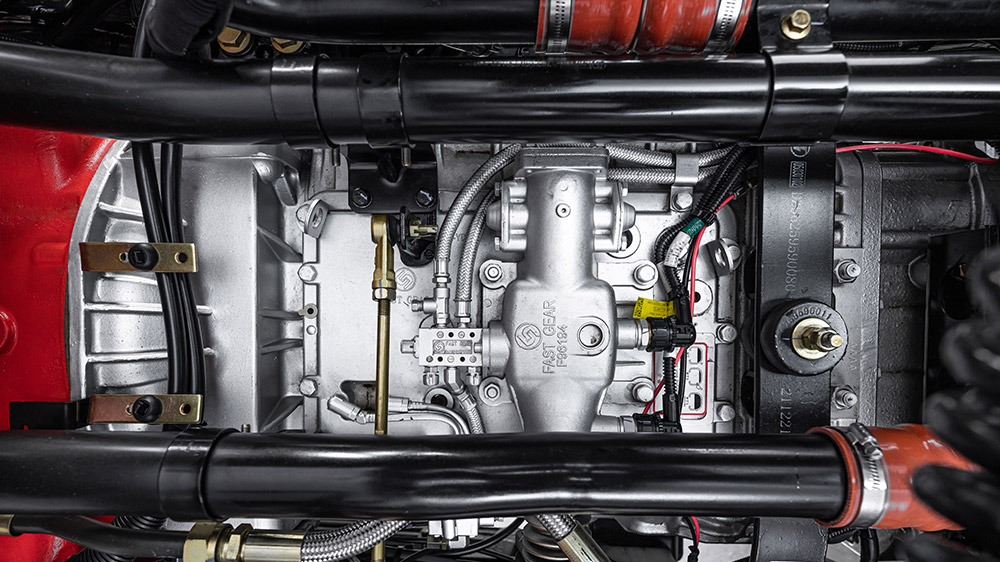

Maintenance-free operation

The FAG bearing axle modules are engineered with a focus on low-friction and maintenance-free operation, while enhancing the vehicle’s transmission efficiency. This design not only optimizes performance but also significantly reduces maintenance expenses for our customers.

Commitment to efficiency and sustainability

Utilizing advanced computational fluid dynamics (CFD) optimization, the vehicle’s redesigned body structure attains a reduced drag coefficient of 0.53. This significant reduction in aerodynamic drag not only enhances the vehicle’s performance but also contributes to a decrease in fuel consumption.

Tranquil in-vehicle atmosphere

The vehicle’s interior is adorned with natural fabric, which accentuates a sense of luxury through its texture. An innovative multi-layer noise reduction system is employed within the cabin, effectively lowering in-cab noise levels to a range of 55-73dB. This is achieved through strategic absorption and isolation of noise, thereby cultivating a tranquil in-vehicle atmosphere.

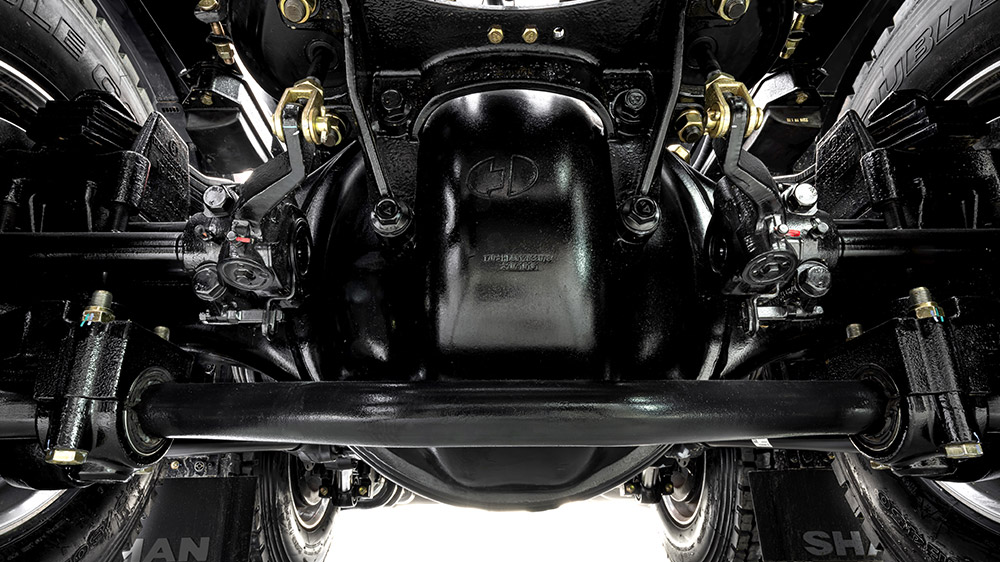

Tour-point air suspension system

The integration of a four-point air suspension system, coupled with lateral shock absorbers, markedly elevates the cabin’s smoothness throughout the driving experience. This suspension design effectively diminishes body vibration and augments passenger comfort, reflecting our dedication to superior ride quality.

The frame structure consists of improved high-strength alloy steel with a 6000-ton compression strength. This material is integrally stamped, which increases its structural width and resistance to deformation.

Impact resistance

The cab utilizes precision robotic welding to ensure better impact resistance and increasing safety. It has complied with the latest European crashworthiness standard of “ECE-R29”.

Excellent electrical system

The X3000 electrical system has passed the rigorous testing with its enhanced electrical components. It has achieved a remarkable performance of over 12 million kilometers of cumulative testing.